Film Materials and Film Coating

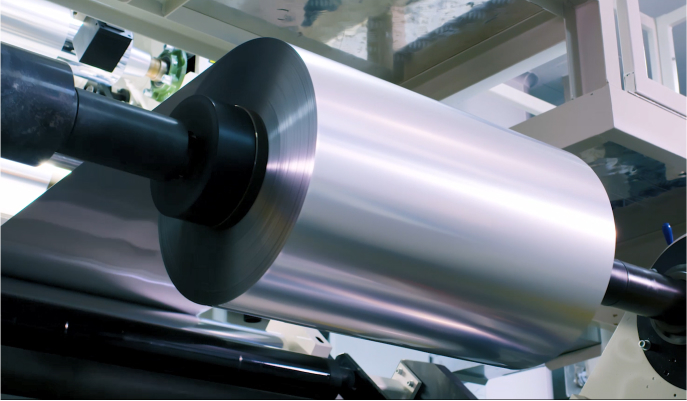

Using advantages acquired by building the integrated layout of Separator, base film, coating and slurry, PTL's Separator Materials and Coating Division has developed a new process of Separator high-speed line and online coating, broke into the international market and expanded the second business growth point. Relying on the new aluminum-plastic film factory in Jiangsu, PTL actively entered the high-end CE and EV pouch cell market, and accelerated the process of localization and substitution.

-

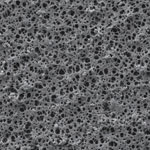

Ceramic + PVDF Coating

Ceramic + PVDF CoatingThis product is coated with ceramic as first layer and then PVDF coating as second layer of the polyolefin separator, thus to realize the tight bonding between the separator and the positive and negative electrodes of the cell, reduce the deformation of the cell, and improve the reaction interface.

-

Fluoropolymer Coating

Fluoropolymer CoatingThis product is a fluorine-free polymer coating on the surface of the polyolefin separator, so that the separator and the positive and negative electrodes of the cell are tightly bonded, the deformation of the cell is reduced, and the reaction interface is improved. The overall thickness is reduced from the traditional 1μm coating to 0.5μm, which is suitable for high energy density projects of lithium-ion batteries.

-

Ceramic + PVDF Hybrid Coated Separator

Ceramic + PVDF Hybrid Coated SeparatorThis product is a ceramic and PVDF hybrid coating on the surface of the polyolefin separator to improve the adhesion between the separator and the positive and negative electrodes of the cell, to reduce the deformation of the cell, improve the reaction interface, and to improve the wettability of the electrolyte.

-

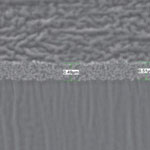

Ultra-Thin Ceramic Coated Separator (UCCS)

Ultra-Thin Ceramic Coated Separator (UCCS)The product obtains a 0.5μm ultra-thin coating by coating the surface of the polyolefin separator with inorganic nano-ceramics, which effectively reduces the thickness of the ceramic coating and maintains the high temperature resistance of 150 °C. On the premise of ensuring the safety performance of lithium-ion batteries, it improves its energy density.

-

Solvent-Based Coated Separator (OBS)

Solvent-Based Coated Separator (OBS)The product is coated by a solvent-based method to obtain an PVDF coating, which has high adhesion performance of the pole piece, fast lithium-ion passing performance, through which obtains fast charging performance.

-

Silver

Silver -

Black

Black

-

Features

Aluminum-plastic packaging film is a packaging material for pouch lithium-ion batteries. It is composed of multi-layer plastic, aluminum foil and adhesive, so it has good plastic shape, hot-pressing sealing, and good isolation. It is suitable as packaging materials for lithium-ion battery cells.

-

Main Application

The products are suitable for the production of CE and EV pouch cell

-

CE

88μ Silver Aluminum Plastic Film (AG055) -

CE

91μ Black Matte Aluminum Plastic Film (AG063) -

PE

Polyethylene (PE) Separator

-

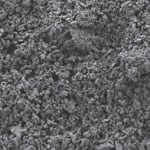

Nano Powder

-

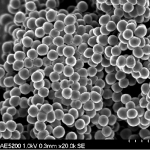

Nano Alumina

Nano AluminaWide range of purity products available

Particle size, morphology, etc. can be customized according to requirements

Slurry products can be customized for direct coating. -

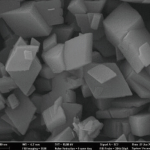

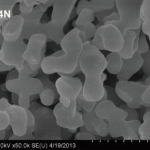

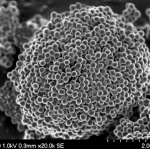

Nano Boehmite

Nano BoehmiteRegular tetrahedral block structure with uniform particles

Slurry products can be customized for direct coating by customers.

-

-

Lithium-ion Battery Electrode Binder

-

LA132/LA133 Special Water-based Binder For Lithium-ion Battery Electrodes

LA132/LA133 Special Water-based Binder For Lithium-ion Battery ElectrodesIndigo original classic products, best-selling for 21 years

Aqueous dispersion of acrylonitrile multipolymer, without emulsifier, thickener and other ingredients

Using water as solvent, the use process is environmentally friendly and safe. -

LA136D/LA136DL Special Water-based Binder For Lithium-ion Battery Electrodes

LA136D/LA136DL Special Water-based Binder For Lithium-ion Battery ElectrodesIndigo's original popular products, the demand has been continuously growing

Aqueous solution of acrylic derivative multipolymer without emulsifier, thickener and other ingredients

Using water as solvent, the use process is environmentally friendly and safe.

-

-

PVDF Resin

-

PVDF Resin For Lithium-ion Battery Binder HEVER 601/701

PVDF Resin For Lithium-ion Battery Binder HEVER 601/701Homopolymerized PVDF powder; rotational viscosity can be customized according to demand; ton bag or carton packaging can be customized to meet various loading needs of customers.

-

PVDF Resin For Lithium-ion Battery Separator Coating HEVER 2601

PVDF Resin For Lithium-ion Battery Separator Coating HEVER 2601Copolymerized PVDF powder; melting point can be customized by demand; ton bag or carton packaging can be customized to meet various loading needs.

-

.svg)